We are Transherba AS, and we are making the biotechnological solutions of tomorrow.

Transherba is a Norwegian biotechnology company.

We believe that a significant contribution to a more sustainable future is recognising the value of the biology around us – and that biotechnology is an essential tool for solving some of the global challenges of today and the future.

We recognize that there will be an increasingly higher demand for biotechnological industrial solutions, and we want to be at the forefront of essential scientific research to realize these. The untapped potential in biotechnology is considerable in food and feed production, bioenergy, veterinary and human medicine, water treatment and fighting pollution.

We aim to identify, characterize, and produce biomolecules (natural and recombinant) for scientific and industrial applications, enabling us to provide industry and society with unique and high-value propositions.

We have expertise and equipment available for handling various molecular aspects at the RNA, DNA, and protein levels and undertake bioprospection by combining fieldwork, benchwork, and bioinformatics. We do whole genome sequencing of organisms of interest, have long experience in different cloning technologies, and can express recombinant proteins in prokaryotic and eukaryotic systems.

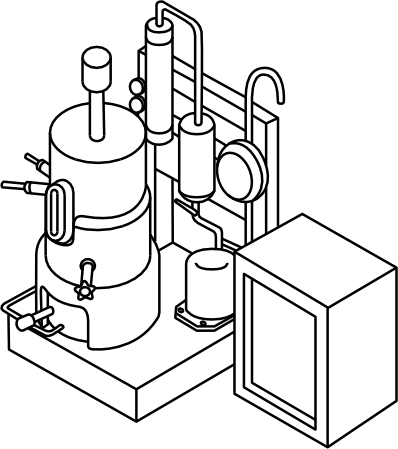

We have the equipment to grow cultures of microbes at very controlled conditions (O2, pH, temperature parameters) and quantities (bioreactors up to 50 liters) for testing upscaling to industrial applications.

PROJECTS

Enzymes converting cellulose into sugar

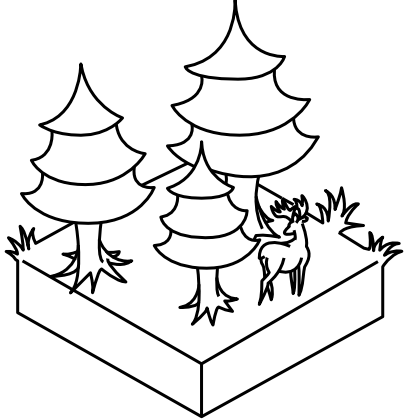

By bioprospecting, we have identified microbial enzymes able to break down the complex structure of wood fibers and convert the wood into sugars. These enzymes will be produced on a large scale for industrial purposes using recombinant technology.

Wood is composed of 40-50 % cellulose, 20-30 % hemicellulose, and 20-30 % lignin. Cellulose, the most abundant organic compound on earth, consists of long chains of glucose molecules, linked with the beta-1,4 glycosidic bonds. Hemicellulose consists of chains of other sugar molecules (mostly xylose and mannose). Lignin, however, does not contain sugars but is a polymer made by cross-linked phenolic precursors.

Theoretically, 1000 kg dry wood (an average log of spruce with 10% water) contains more than 700 kg sugar (490 kg glucose and 230 kg xylose), which can be fermented to around 450 liters of ethanol. The sugar can be used as feed and food ingredients, and the ethanol can be applied as biofuel or starting material for other industrial applications. In addition, the wood contains several other valuable organic compounds that the industry can use to produce products like carbon fibers, glue, and bioplastics.

The challenge is, however, how to break down the wood. Cellulose fibers have a very compact structure and are surrounded by hemicellulose and hydrophobic lignin, they are therefore very resistant to water and attacks by enzymes. It is, therefore, a curious fact that some animals, like the moose, during the wintertime can have their nutritional needs covered by almost exclusive feeding on trees. The explanation is that the animals harbor microorganisms in their rumen that can break down the woody materials.

By bioprospecting, our company has identified microorganisms with enzymes able to attack and split the complex structure, thereby releasing the sugars. We have conducted whole genome sequencing of several of these microbes and have identified the genes encoding these enzymes.

PROJECTS

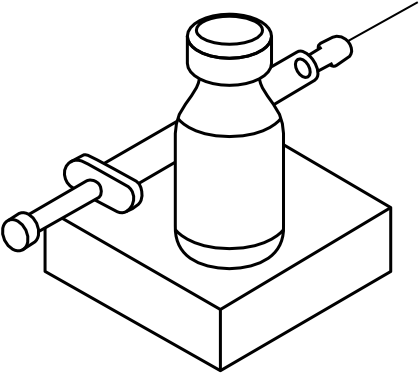

Vaccine Development

We have the equipment, access to laboratory facilities, and knowledge required for the different vaccine development approaches.

We have initiated a project to develop a vaccine against a zoonotic disease. The approach will encompass “recombinant antigen” and “mRNA vaccination” technologies.

A wide range of microbes (virus, bacteria, fungi, protozoa) might cause diseases in humans and animals. Each of these microbes often has its unique mode of infection. For example, the virus causing influenza and the bacterium causing tuberculosis will infect through the airway and lungs, whereas rotavirus and the bacterium Salmonella enter the body through the gastro-intestinal tract. Furthermore, the yellow fever virus, the bacterium Borrelia and the protozoa causing malaria are transmitted through the skin by the bites of insects. In addition, each of these microbes may have particular types of cells or tissues where they prefer to multiply. Influenza virus replicates mainly in epithelial cells of the respiratory tract; the tubercle bacilli multiply inside macrophages, while the malaria parasite multiplies inside red blood cells.

When designing a vaccine, these differences in how and where a microbe infects the body and how and where it prefers to multiply must be considered. A vaccine aims to mount a protective immune response to prevent the microbe from invading and multiplying in the body. At the same time the vaccine should not give any severe side effects. There are different strategies for vaccine development: Vaccines consisting of killed or attenuated microbes, vaccines based on recombinant antigens, DNA vaccines, or mRNA vaccines. In all such approaches, one might add adjuvant ingredients (like aluminum salts or squalene oil) that will increase the immune response to the antigen and eventually modulate the response in a more protective direction. There is no standardized method to make a vaccine. An approach that works well for one given microbe might not work for another.

The ongoing project, which includes development of both diagnostic methods and vaccines against a zoonotic disease, is supported by The Sustainability Foundation – a collaboration between The Norwegian Agrarian Association and The Gjensidige Foundation https://www.bondelaget.no/barekraftfondet/.

Meet our team

We believe that making challenging things happen is a prerequisite to having a solid foundation in the relevant area of expertise. Only then is it possible to creatively solve problems in a field such as biotechnology and create solutions that can have an impact.

Vidar Bakken

(CEO). Dr.odont. from the University of Bergen. He has been a professor of microbiology and immunology for more than 20 years at the University of Bergen. He has initiated and been PI of projects focused on stress proteins (HSPs), biofilm, and bacterial invasion. The primary objective has been to identify and characterize virulence factors of oral bacteria (periodontal pathogens) that may be vaccine candidates or targets for diagnosing and treating periodontal diseases and associated inflammatory systemic diseases. He also has experience as a researcher in Intervet Norbio AS with developing and producing fish (salmon) vaccines. In recent years, his R&D focus has been on cellulases from rumen bacteria and their possible industrial applications.

Audun Helge Nerland

(CTO). Dr.scient. from the University of Oslo. He has a strong background in molecular biology, immunology, virology, bacteriology, and parasitology. He worked for 10 years as a R&D senior scientist for the private industry (Intervet Norbio AS) with vaccine development and production. Then he worked for 10 years at the Institute of Marine Research, conducting fundamental research on infectious diseases of fish. For the following 13 years he was a professor at the University of Bergen, where his research focuses on tropical infectious diseases. From 2004-2013, he was a member of VKM (The Norwegian Scientific Committee for Food and Environment), performing risk assessments of genetically modified organisms (GMO). He has extensive experience in whole genome sequencing, transcriptomics, metagenomics, gene cloning, and expression of recombinant proteins.

Knut Olav Strætkvern

Dr.scient. from the University of Bergen and a civil engineer from NTH, Trondheim. He has a broad research background in bioprocess technology from academia and industry partners. He has specialized in the downstream technology of functional proteins and bioactive plant molecules. As an Inland Norway University of Applied Sciences professor since 2011, he has led the bioprocessing group on several projects dealing with biomass refining, microbial fermentation, and enzyme technology on lignocellulosic biomass. He is competent in bioprocess development, including experimental design, scale up, process optimization and modelling, and economic analysis. He has consulted several companies in food processing and industrial biotechnology and served as expert reviewer for the Research Council of Norway and EU research programs.

Geir Skogerbø

Dr. Scient from the Norwegian University of Life Sciences (NMBU). He has worked as an associate professor at Inland Norway University of Applied Sciences (12 years) and as a senior researcher at the Institute of Biophysics of the Chinese Academy of Sciences (10 years). He has been involved in research on transgenic plants and various aspects of noncoding RNAs. He is presently employed by the IVAR IKS public company in Stavanger.

Do you want to get in touch?

We are always interested in talking to people who share our passion for biotechnology and its applications. Please send us an email if you want to get in touch.